The development of intracrystalline mesoporosity within zeolites has been a long-standing goal in catalysis as it greatly contributes to alleviating the diffusion limitations of these widely used microporous materials. During my presentation, I will discuss the main techniques that have been developed during the last years to produce zeolites with controlled mesoarchitectures comparing the different methods, their advantages and limitations. Among the different techniques used to characterize the composition, porosity and structure of these materials, I will present unprecedented insights on the formation of intracrystalline mesoporosity in zeolites obtained by in situ synchrotron X-ray diffraction, Atomic Force Microscopy (AFM), and Liquid Cell Transmission Electron Microscopy (Liq-TEM). By combining experimental results and theoretical calculations, the presence of intracrystalline mesoporosity was recently confirmed. Moreover, through the direct observation of individual zeolite crystals by in situ AFM and Liq-TEM, we have been able to provide the first time-resolved visualization of the formation of mesoporosity in zeolites.

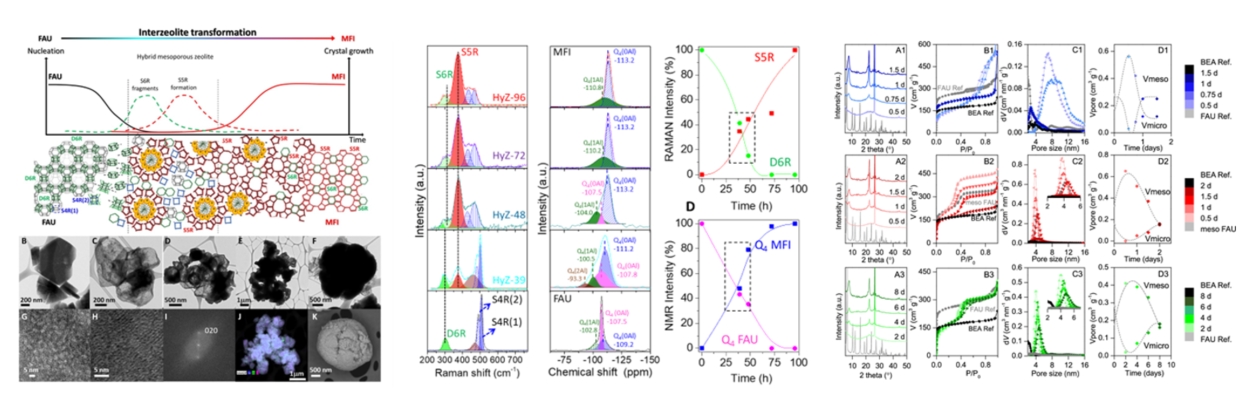

During the presentation, I will describe a new strategy for the synthesis of superior hierarchical catalysts, which lack long-range order but at local scale contain zeolite building units. [1,2] In fact, they are made out of fragments of one or even various zeolite structures and display improved accessibility, strong acidity, and excellent stability. Because of these features, they effectively catalyze reactions involving very bulky molecules, which currently are produced using highly corrosive homogenous catalysts (Fig. 1). To achieve this goal, we built on a well-known technique, namely the interconversion of zeolites, which we interrupted at different times to yield the desired amounts of building units of the zeolites involved. The addition of quaternary ammonium surfactants during their preparation allows the development of well-defined mesoporosity and large surface areas. Using this simple procedure, we were able to produce families of materials with controlled amounts of different zeolitic building units and, consequently, optimize their catalytic performance for various reactions including Friedel-Crafts alkylations and Claisen-Schmidt condensations, and the cracking of 1,3,5-triisopropylbenzene.

Figure 1. Textural, structural, and morphological characterization of some intermediates of the interconversion of zeolite FAU into MFI and BEA structures.

An important advantage of this strategy is that the physicochemical properties and, therefore the catalytic performance, of the hierarchical catalysts can be finely tuned by simply stopping the interzeolite transformation at different times. This creates countless opportunities for the development of hierarchical catalysts [3] with optimized properties and superior catalytic performance for those reactions in which zeolites present significant diffusion limitations (Fig. 1). This paves the way for the fabrication of hybrid hierarchical catalysts with optimized properties for those processes in which the combined use of different zeolites yields improved performance.

The presence of this mesoporosity was further evidenced through ex situ gas adsorption, which also confirmed the preservation of most of the microporosity of the zeolites. All these new insights, obtained by combining a number of time-resolved techniques, are an example of the enormous potential of current in situ characterization methods for the rational design of hierarchical zeolites with superior properties and optimal catalytic performance as it has been proved at lab, pilot plant, and industrial scale.

In several operations in a number of refineries, a steady increase in LPG olifinicity was observed when replacing the incumbent FCC catalyst with another containing our mesostructured Y zeolite. Commercial data confirmed what we observed in equilibrium catalysts, i.e. a gradual increase in the LPG olefinicity, as the concentration of the FCC catalyst containing mesostructured Y zeolite in the circulating inventory steadily increased. Furthermore, a very valuable increase in gasoline octane is typically observed due to a higher concentration of olefins in the lighter gasoline fraction.

The commercialization of hierarchical zeolites, first through the MIT spin-off Rive Technology and now by Shell and GRACE, as superior refining catalysts is an example of academic entrepreneurship, which is expected to foster the development of new hierarchical zeolites and their use in both existing processes and new opportunities. Finally, I cover other applications of hierarchical zeolites in catalysis, including biomass valorization and fine chemistry, ending with a personal view of the new directions, and opportunities in this field.

References:

[1] M. Mendoza-Castro, Z. Qie, N. Linares, J. García-Martínez, Nat. Comm., DOI: 10.1038/s41467-023-36502-3

[2] M. Mendoza-Castro, E. De Oliveira-Jardim, N.T Ramírez-Márquez, C. A. Trujillo, N. Linares, J. García-Martínez, J. Am. Chem. Soc. 2022, 144, 11, 5163–5171

[3] A. Sachse, J. García-Martínez, J.; Chem. Mater. 2017, 29 (9), 3827– 3853

Professor, UNIVERSITY OF ALICANTE