26 February, 2020

Unconventional perovskites with an inverted structure see a leap in efficiency and longevity with an amine-based additive.

Long-lived inverted perovskite solar cells can achieve efficiencies close to that of highly efficient yet fragile conventional perovskite solar cells, researchers at KAUST have shown. The discovery could lead to perovskite solar panels that have operational lifetimes and light-capturing efficiencies that rival traditional silicon solar panels, but that are significantly simpler, less energy-intensive and less expensive to make.

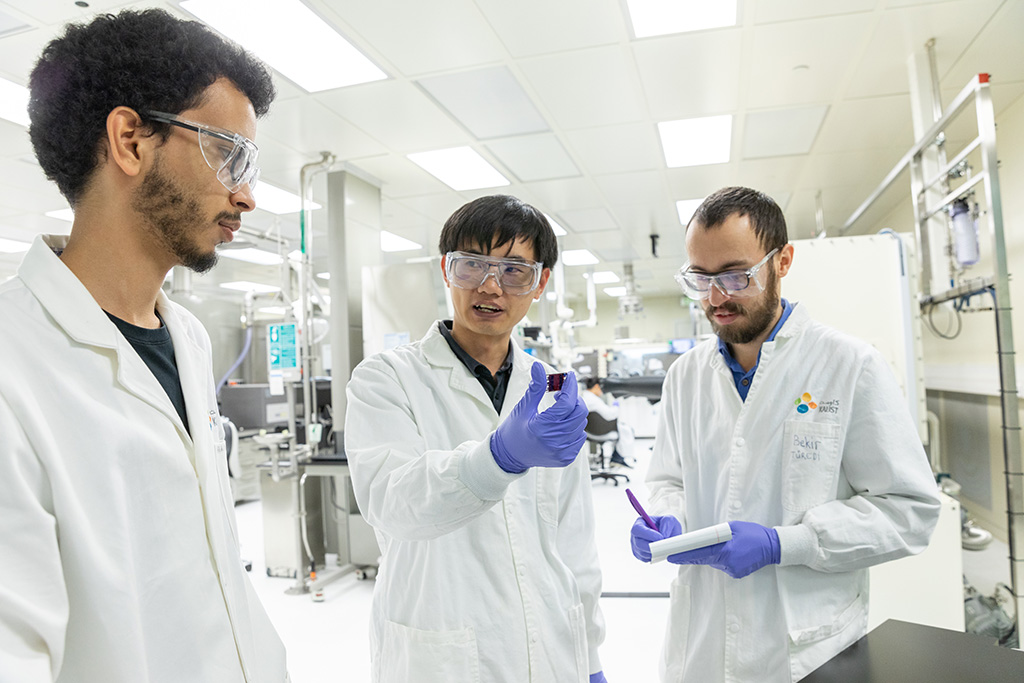

In the lab, metal halide perovskite solar cells have jumped from power conversion efficiencies of 3.8 percent to 25.2 percent in just a decade. “Conventional perovskite solar cells, with their component layers arranged in an ‘n-i-p’ structure, offer the highest efficiencies,” says Osman Bakr from the KAUST Catalysis Center, who led the research. However, these devices require ionic dopants, which are unstable and shorten the solar panel’s lifetime.

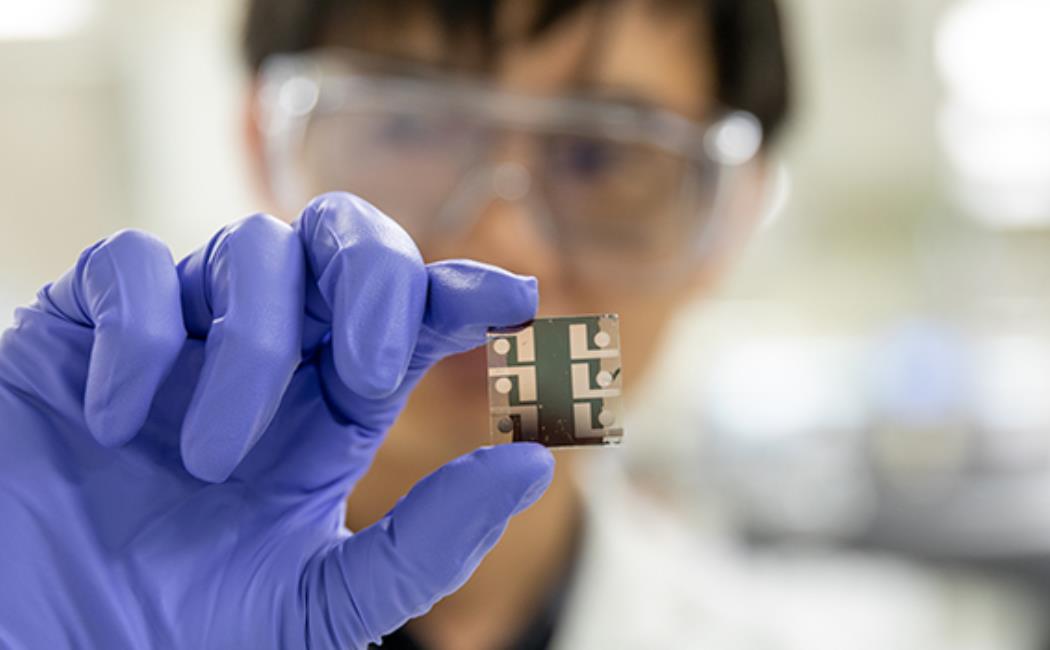

“Inverted ‘p-i-n’ perovskites do not need the unstable dopants, extending their operational lifetime,” says Xiaopeng Zheng, first author of the study. “Unfortunately, the efficiencies of inverted perovskite solar cells lag significantly behind those of regular structured devices,” he says. Until now, the best inverted perovskite reached 20.9 percent efficiency.

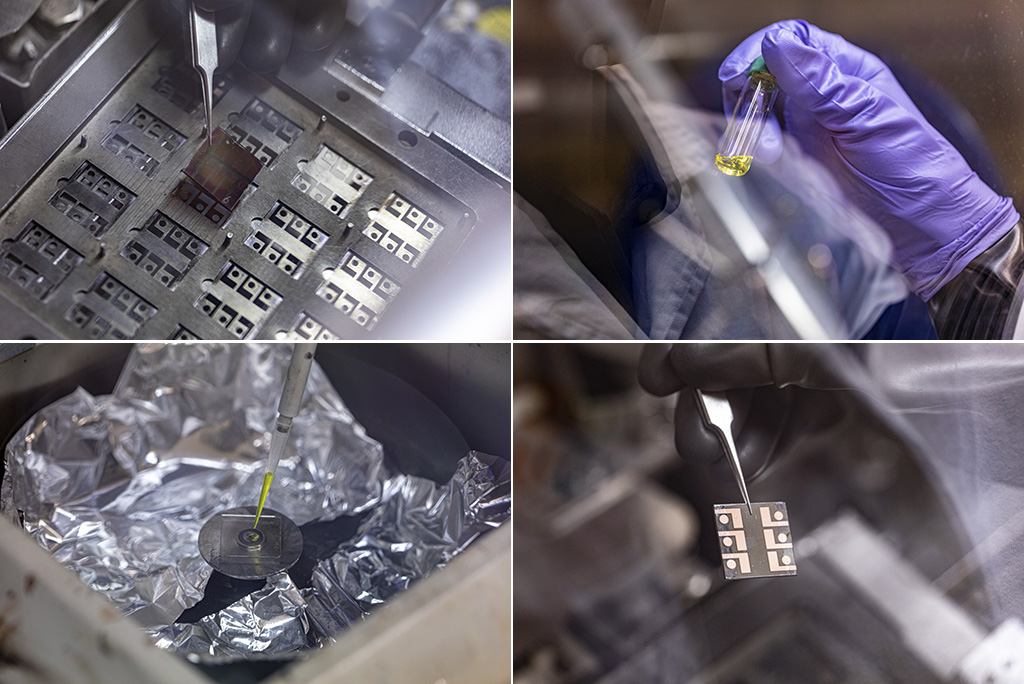

Now Bakr and colleagues, in collaboration with researchers from the University of Toronto in Canada, have significantly improved inverted perovskite cell efficiency. By adding long-chain alkylamine ligands (AALs) into the mixture during perovskite production, the team created an inverted perovskite solar cell with enhanced stability and with a record-certified efficiency of 22.3 percent. “Just a trace amount of alkylamine was enough to improve the structural and optoelectronic properties of the perovskite in multiple ways,” Zheng says.

Adding long-chain AALs into the perovskite mix during fabrication meant the tails of the AALs interacted—this aligned neighboring grains to reduce boundary defects in the final perovskite film. As the perovskite grains came together, the AALs were pushed to the outer surface, forming a protective coating. The amine head of each AAL molecule could also fill point defects in the perovskite structure. Overall, adding long-chain AALs boosted the electrical output of the material in sunlight and also further improved stability and longevity.

“In the next stage of our research, we will scale up the production of perovskite cells to achieve a high-performance and market-ready product,” Zheng says. “Developing a scalable method for creating large-area, high-quality perovskite films on different surfaces, including flexible substrates and silicon wafers, will overcome the key remaining hurdle to commercialization,” he says.