26 October, 2022

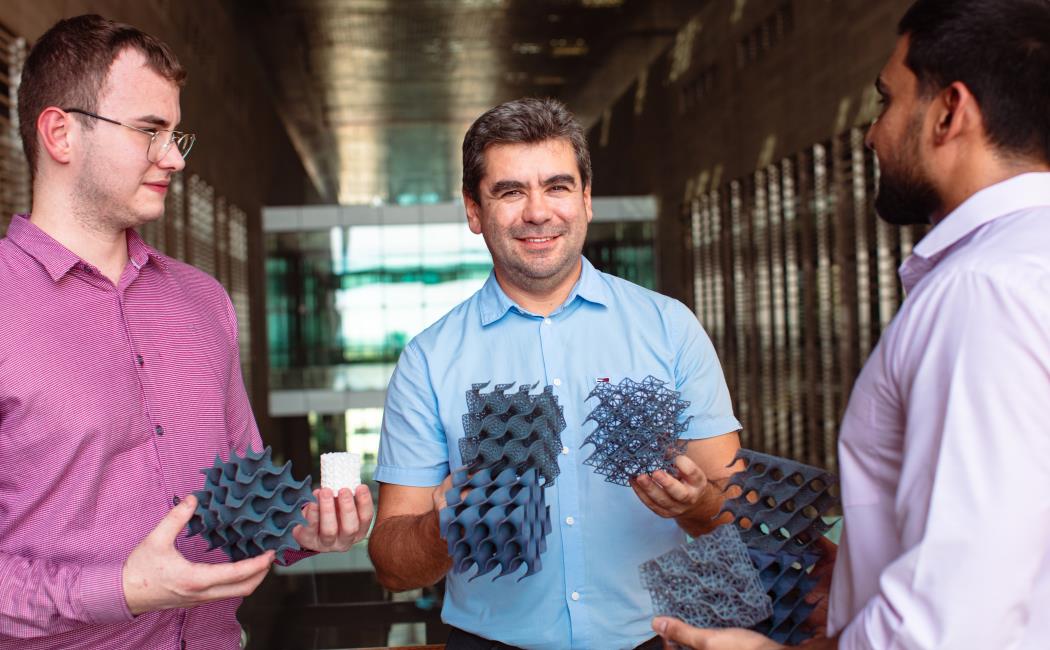

Photo Anastasia Serin

Concepts of shape and time are bringing new thinking to the production of next-generation equipment and materials for chemical and pharmaceutical industries.

KAUST’s Carlos Grande and his team are looking specifically at novel ways to develop chemical reactors and separation processes from a mathematical design perspective.

“Time is perhaps the most important variable in many discontinuous or cyclical processes. Shape is also important, in terms of enhancing transport, heat transfer, mass transfer and pressure drop. Both the time and shape variables ultimately define the viability of a given process, such as a chemical reaction,” Grande explains.

Working with other groups that make materials and catalysts, Grande’s team tries to design everything around the time and shape variables to create the best environment to enhance their properties.

“When it comes to new shapes, performance can benefit enormously if we can manufacture new parts with an improved and tailored shape for a specific application,” he says.

“Performance can benefit enormously if we can manufacture new parts with an improved and tailored shape for a specific application”

He cites the example of a generic reactor. “If in one process we can improve heat and mass transfer, we can significantly reduce the size and energy consumption of the equipment.”

Many available reactors and separation processes are off the shelf. They are available in catalogues and have some customization but, in practice, their shape influences their operation, controlling the chemistry and energy consumption.

“We want to manufacture bespoke reactors and separation processes. The idea is that if the shape can improve the transport properties, the chemistry will control the final operation.”

He likens it to the case of a shirt that does not quite fit. “So, to get a better fit, we may need to diet or do some exercise to reduce our volume. Whereas a tailored shirt will be cut with the right shape to fit perfectly.”

“If we cut the fabric with the right shape from the beginning, we will also avoid losing pieces of fabric, making the process more sustainable — a potential advantage of additive manufacturing if parts are well designed.”

Computer simulations have led to great advances in the field of industrial design, but, according to Grande, the real revolution involves aligning design, modeling and 3D printing.

“We can now create customized shapes with great complexity and less material. This means we can reduce energy and material consumption even at the construction phase of the process.”

Customization of new shapes that can be 3D printed is one of the group’s main research topics. Importantly, the entire process is digital – they design and model each piece of equipment and will only produce something once they are satisfied with the simulated results.

The team is also focused on the internal elements used in reactors and separator units, whose main role is to enhance the area of contact, either to improve mass transfer or heat transfer.

“The design of these elements is complex; a large increase in surface area can be associated with a higher pressure drop, so the process can be shorter but still consume more energy,” says Grande.

They are trying to find novel designs that enhance mass/energy transfer and keep pressure drop low.

“According to our simulations, we can design new internal elements with an increase in heat transfer properties of 15-20 percent and a 30 percent lower pressure drop. This means that the new designs are twice as efficient,” says Grande.

And in the near future, he hopes to involve machine learning or other artificial intelligence techniques to achieve real optimized designs.

Grande says that training is lacking to help engineers design the next generation of reactors. “This lack of competence is preventing methods like 3D printing becoming more widely used in industry.” He believes KAUST has a niche opportunity to lead in this sector.